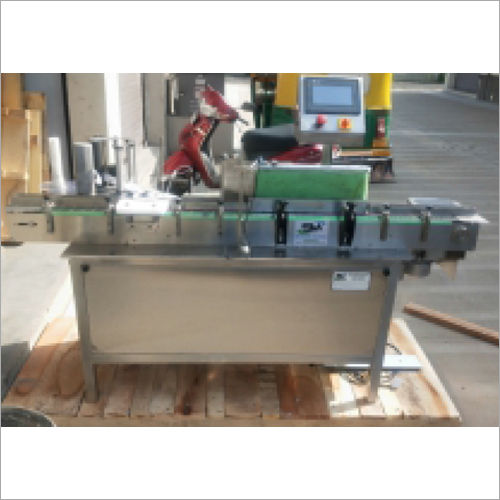

Sticker Labeling Machine

100000 आईएनआर/टुकड़ा

उत्पाद विवरण:

- प्रॉडक्ट टाइप

- मटेरियल Stainless Steel

- एप्लीकेशन Labeling bottles, jars, vials, containers

- कम्प्यूटरीकृत

- स्वचालित ग्रेड

- कंट्रोल सिस्टम

- ड्राइव टाइप

- Click to view more

X

स्टिकर लेबलिंग मशीन मूल्य और मात्रा

- टुकड़ा/टुकड़े

- टुकड़ा/टुकड़े

- 5

- Corrosion resistant structure

- Fiber optic based label and container sensing

- 300 mm Maximum

- 30 mm to 120 mm

- 15 mm x 15 mm to 150 mm x 300 mm

- Single Side or Double Side Labeling

- Touch Screen HMI

- 75 mm

- Up to 25 m/min

- Less than 70 dB

स्टिकर लेबलिंग मशीन उत्पाद की विशेषताएं

- Approx. 300 kg

- Labeling bottles, jars, vials, containers

- Up to 120 labels/min

- 220-240 V

- Stainless Steel

- ±1 mm

- 2000 mm x 900 mm x 1500 mm

- Corrosion resistant structure

- Fiber optic based label and container sensing

- 300 mm Maximum

- 30 mm to 120 mm

- 15 mm x 15 mm to 150 mm x 300 mm

- Single Side or Double Side Labeling

- Touch Screen HMI

- 75 mm

- Up to 25 m/min

- Less than 70 dB

स्टिकर लेबलिंग मशीन व्यापार सूचना

- प्रति सप्ताह

- हफ़्ता

उत्पाद विवरण

Sticker Labeling Machine is widely suitable for different material of container and label. It is aesthetically designed and precision-engineered for its higher performance and durable work life, is being offered to all our clients. This machine is manufactured using supreme grade quality components that is sourced from reliable vendors of the market keeping in mind set industry norms. Apart from this, Sticker Labeling Machine can be availed from us at market leading price.

Superior Labeling Precision and Efficiency

Engineered for high-speed environments, our Sticker Labeling Machine offers exceptional accuracy and consistent labeling even at capacities reaching 120 bottles per minute. It achieves optimal performance through a robust electric drive, PLC-based controls, and advanced sensing systems, making it ideal for both single and double-sided labeling on various containers.

User-Friendly Operations and Maintenance

This machine features an intuitive touch screen HMI for seamless operation, allowing for easy adjustments and monitoring. Designed for minimal maintenance, its corrosion-resistant stainless steel construction ensures durability and long service life, lowering operational costs over time. The automated design further streamlines your labeling process, maximizing productivity.

FAQs of Sticker Labeling Machine:

Q: How does the Sticker Labeling Machine handle different bottle and label sizes?

A: The machine is engineered to accommodate bottles with diameters from 30 mm to 120 mm and labels ranging from 15 mm x 15 mm to 150 mm x 300 mm. Its adjustable guides and flexible configuration make it suitable for a wide variety of container shapes and sizes, ensuring precise labeling across all compatible products.Q: What is the typical process for operating this labeling machine?

A: Operation is straightforward: simply load label rolls (with inner diameter 75 mm and outer up to 300 mm) onto the spindle, adjust the conveyor for the target container, set parameters via the touch screen HMI, and start the machine. The intelligent fiber optic sensor system ensures accurate detection and placement for both containers and labels.Q: When and where is this machine best utilized?

A: This labeling machine is best suited for high-throughput production environments such as bottling plants, pharmaceutical lines, food and beverage manufacturers, and cosmetics industries. It excels wherever precise, high-speed labeling of bottles, jars, vials, or other containers is required.Q: What are the primary benefits of using this labeling machine?

A: The main benefits include high labeling speed (up to 120 labels per minute), 1 mm placement accuracy, low maintenance requirements, corrosion-resistant construction, and quiet operation (<70 dB). It helps increase productivity, reduce operational errors, and maintain high product presentation standards.Q: How does the sensing system contribute to accuracy and reliability?

A: This machine utilizes advanced fiber optic sensors to detect label presence and container positioning. This technology ensures flawless alignment and consistent application, significantly reducing labeling errors and material wastage during operation.Q: Is the machine easy to use and adjust for different container types?

A: Yes, the user-friendly touch screen HMI simplifies adjustments for varying container sizes and label types. Operators can quickly change settings and monitor performance in real-time, making it easy to switch between different products without lengthy downtime.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email