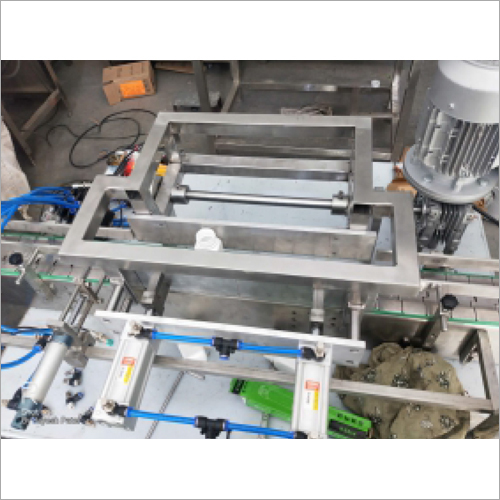

Air Jet Vacuum Cleaning Machine

10000.00 आईएनआर/टुकड़ा

उत्पाद विवरण:

- कनेक्टिविटी टाइप Standalone

- पावर सोर्स

- विशेषताएँ Auto bottle feeding, Compact design, Noise reduction, Inbuilt vacuum system

- एक्सेसरीज़ Nozzles set, Spare filters

- टैंक की क्षमता Not applicable (no water required for dry cleaning)

- कंट्रोल सिस्टम PLC Controlled

- दबाव रेटिंग Adjustable

- Click to view more

X

एयर जेट वैक्यूम क्लीनिंग मशीन मूल्य और मात्रा

- टुकड़ा/टुकड़े

- टुकड़ा/टुकड़े

- 1

- SS 304 Grade

- Emergency Stop, Protective Covers

- 1800 x 900 x 1500 mm (Typical)

- SS Slat Conveyor

- Approx. 300 kg

- 30ml to 1 Litre (Customizable)

- Pharmaceutical, Food & Beverage, Chemical, Distilleries

- <= 70 dB

- 2, 4, or 8 (Depending on Model)

- Approx. 36-40 cfm

एयर जेट वैक्यूम क्लीनिंग मशीन उत्पाद की विशेषताएं

- 24 to 48 bottles per minute

- Standalone

- 220V / 50Hz

- Adjustable

- High suction capacity

- Not applicable (no water required for dry cleaning)

- PLC Controlled

- Nozzles set, Spare filters

- Auto bottle feeding, Compact design, Noise reduction, Inbuilt vacuum system

- SS 304 Grade

- Emergency Stop, Protective Covers

- 1800 x 900 x 1500 mm (Typical)

- SS Slat Conveyor

- Approx. 300 kg

- 30ml to 1 Litre (Customizable)

- Pharmaceutical, Food & Beverage, Chemical, Distilleries

- <= 70 dB

- 2, 4, or 8 (Depending on Model)

- Approx. 36-40 cfm

एयर जेट वैक्यूम क्लीनिंग मशीन व्यापार सूचना

- प्रति महीने

- दिन

उत्पाद विवरण

Air Jet Vacuum Cleaning Machine is a devised to ensure simple & modular operation, where each individual bottles/jar is positively washed with maximum washes. Its a perfect balanced of bottles/jars cleaning machines with CGMP concept. This machine is designed and developed from the superior quality raw material under the strict vigilance of talented quality control executives at our end. We provide this range of Air Jet Vacuum Cleaning Machine at moderately prices.

Optimized for Versatile Bottle Cleaning

Engineered to handle bottle sizes from 30ml to 1 litre, the Air Jet Vacuum Cleaning Machine adapts to various production requirements. Its customizable design, combined with options for 2, 4, or 8 cleaning heads, makes it suitable for both small and large-scale operations. This automation not only accelerates cleaning but also minimizes manual labor.

Stainless Steel Durability for Industrial Reliability

The frame and conveyor are constructed from high-quality SS 304 stainless steel, ensuring corrosion resistance and consistent performance even in demanding environments. This material selection guarantees longevity and compliance with hygiene standards crucial for applications in pharmaceutical and food processing industries.

Advanced Safety and User-Friendly Features

Safety is a priority, with protective covers, an emergency stop, and a fully enclosed cleaning area. Its auto bottle feeding system, PLC controls, and inbuilt vacuum system deliver efficient operation while reducing operator intervention. Sound insulation keeps noise at or below 70 dB, ensuring a comfortable workplace.

FAQs of Air Jet Vacuum Cleaning Machine:

Q: How does the Air Jet Vacuum Cleaning Machine clean bottles without water?

A: The machine utilizes high-pressure compressed air jets combined with a powerful inbuilt vacuum system to dislodge and extract dust or particles from inside bottles. This dry cleaning method eliminates the need for water, making it suitable for industries with strict hygiene or moisture constraints.Q: What bottle sizes and shapes can the machine handle?

A: The system is customizable to clean bottles ranging from 30ml up to 1 litre. Its adjustable nozzles, cleaning heads, and slat conveyor accommodate a wide variety of bottle shapes commonly used in pharmaceutical, food, chemical, and distillery applications.Q: When is air jet vacuum cleaning preferred over traditional wet bottle cleaning?

A: Air jet vacuum cleaning is ideal when water-based washing is unsuitable, such as for products sensitive to moisture or contamination. It is especially valuable in industries where bottle interiors must be dry and particle-free before filling, like pharmaceuticals and food processing.Q: Where can this machine be installed and operated?

A: Designed for industrial settings, it is best installed in bottling plants, production floors, or cleanrooms of pharmaceutical, beverage, chemical, or alcohol manufacturing facilities. Its compact footprint allows easy integration alongside existing processing or packaging lines.Q: What benefits does the air jet vacuum cleaning process offer to businesses?

A: This process delivers quick, residue-free cleaning, reducing labor costs and improving production speed. It conserves resources by eliminating water use, which also reduces cleaning time and risk of contamination. The PLC-controlled system ensures precise, repeatable operation for consistent bottle hygiene.Q: How is operator safety maintained during machine operation?

A: The machine features emergency stop controls, protective covers over moving parts, and an enclosed cleaning area to prevent accidental exposure to air jets or vacuums, thereby safeguarding personnel during routine operation and maintenance.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email